hen the C4 Corvette-based ZR1 hit the streets in 1990, its high-winding LT5 engine put the world on notice. Performance was back at Chevrolet, and the ZR1 was its king. The all-new, dual-overhead cammed engine was such a deviation from the norm that it overshadowed many of the other benefits of the ZR1 Corvette. It also intimidated quite a few of GM’s technicians as well. Thankfully, Dirk Paris isn’t intimidated by the LT5’s uniqueness. In fact, he used it to great effect in his LT5-swapped 1989 Camaro IROC Convertible.

Building The LT5 Engine

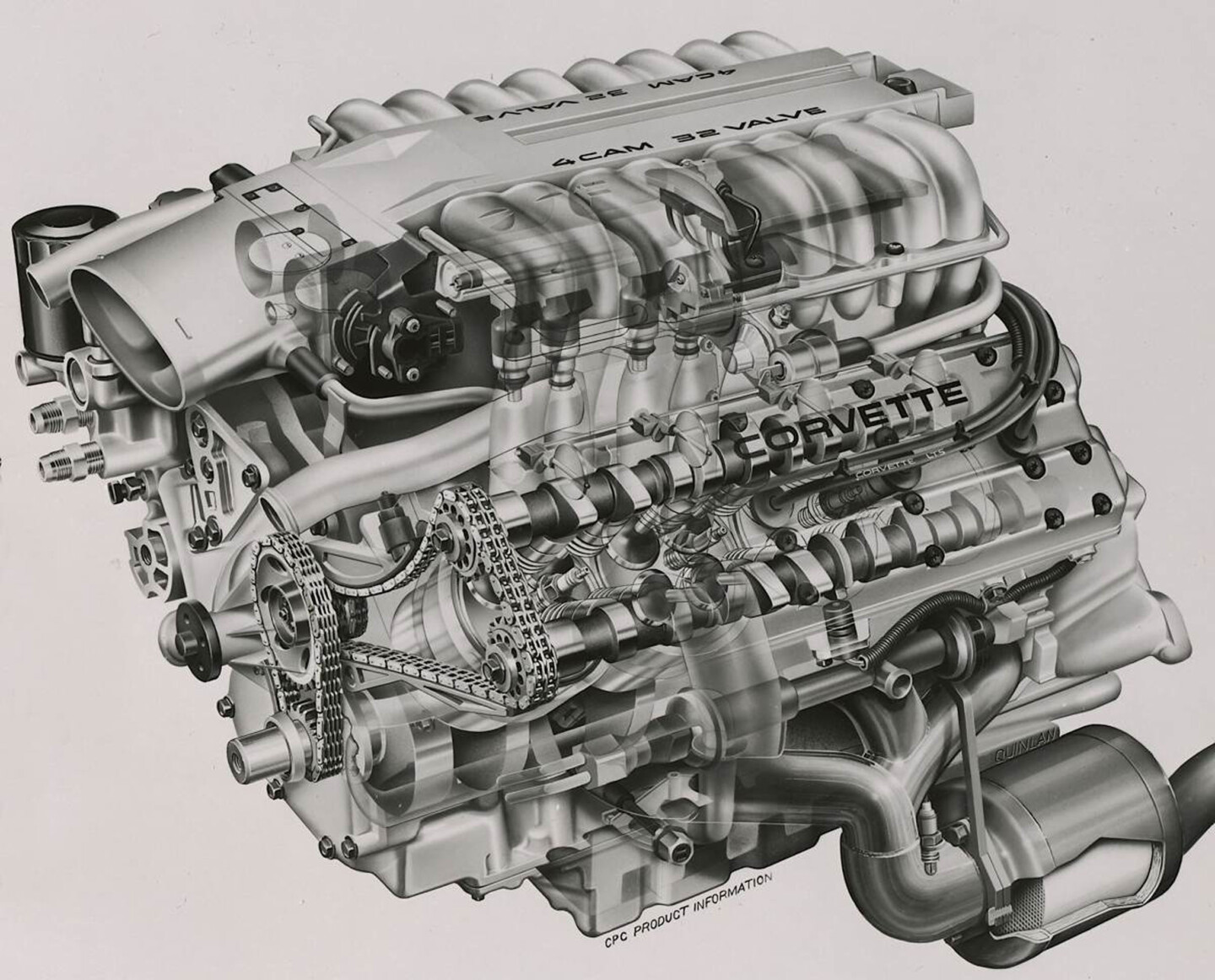

The LT5’s all-aluminum block and heads were works of art. The machining processes had never before been attempted to such a level by GM or any other auto manufacturer. That is why Chevy went to the knowledgeable engineers at Lotus in the United Kingdom and Mercury Marine’s MerCruiser division in Stillwater, Oklahoma to build the engine. After several phases of refinements, the engine was ready for production by MerCruiser, who would then ship them to Bowling Green, Kentucky. There the engine would join the car as it worked its way down the assembly line. If there were to be a significant problem with the engine once the car reached the dealer level, GM technicians would simply remove the engine and ship it back to the folks at MerCruiser.

The LT5 was an engineering marvel when introduced. Its complexity intrigued many and struck fear in technicians. The engine has enjoyed a devoted following ever since its introduction.

The engine’s foreign upbringing, its non-typical Chevy V8 style, and the additional cost of the ZR1 option gave the LT5 a level of exotic-ness among many enthusiasts. ZR1 Corvettes built between 1990 and 1995 are still savored by collectors and enthusiasts who relish the engine’s 7,000 RPM redline and up to 405 horsepower.

Dirk’s 1989 Camaro IROC Convertible

While engineers at GM, Lotus, and Mercury Marine were still working out the details of the not-yet-production LT5 engine, Dirk’s Camaro was already out of the assembly plant’s doors and hitting the highway. Where it spent most of its time is uncertain, but our story begins in 2014, with Dirk finding the drop-top Camaro in a Craigslist ad. It was previously some kid’s high-school car, but when Dirk came to look at it, the car had been sitting along the road, languishing for the past six years.

This is how Dirk found the Camaro in the Craigslist ad. The engine and transmission were toast, so he trailered the vehicle home.

Dirk bought the car, which could be described conservatively as a “Mechanic’s Special.” The car was amazingly rust-free, but the interior had a level of mold and odor typically reserved for crime scenes or community dumpsters. A thorough cleaning inside and out moved the needle to an acceptable level and gave Dirk an opportunity to assess the car’s condition.

“The 5.0L TPI engine and trans were shot and it did not run very long and leaked like a sieve”, Dirk recalls. He decided that restoration wasn’t the goal, so he found a wrecked 1989 IROC Camaro with a 5.7L TPI and the same dove grey interior. Dirk swapped the engine and transmission, along with the other car’s rear axle assembly. Dirk also rebuilt the suspension at this time using UMI Performance components and strengthened the Camaro’s body with UMI subframe connectors. The steering box was rebuilt locally by Red Head Steering Gears in Seattle.

Dirk did a lot of cleaning and swapping of interior pieces to get his Camaro’s innards back up to grade.

When the second automatic transmission gave up the ghost, Dirk located a T56 transmission from a 1997 Camaro SS. He had Tick Performance rebuild the transmission and installed a Fidanza flywheel with a McLeod clutch. He then finished bolting the bell by drilling and tapping the engine block for an additional mounting bolt. The fun factor went way up since upgrading from auto to the T56, even behind the oh-so-stock Tune-Port 5.7-Liter engine.

With the car now hitting the road, Dirk focused on the bodywork. He spent four months in 2018 prepping the car for paint by swapping out one door, a fender, the rear bumper cover, and the hood. He then coated the entire car in Lexus tri-coat White paint. To help raise the car’s street cred, he also installed a set of Hawks 17-inch, IROC-Z wheels and bumped the rear diff’s ratio to 3.73:1, and added a stud girdle rear differential cover. At this point, Dirk was hitting the highway and enjoying his IROC at various shows and events in the Pacific Northwest.

Transplanting The LT5 Engine

As we all know, the heat of a warmed-over ride eventually cools and Dirk was looking for a way to bump the performance of his Camaro significantly. Chevy’s Tune-Port engine is a solid performer, but not known for belting out high-revving power and Dirk was looking for a way to use more of the tachometer as he was rowing through the gears.

One blip of the throttle will tell the TPI-calibrated tachometer that the Tune-Port has long since been removed!

That’s where the sibling Chevy’s LT5 engine comes perfectly into the picture. “In 2019 the upgrade bug hit me once again when I saw a 1990 ZR1 LT5 engine for sale with only 17,000 miles on it”, he says. “The LT5 is one of my favorite engines of all time and I had to have it!” Dirk reports that his wife and several other folks questioned his sanity because he had just completed the car with the new paint and a detailed 5.7 TPI engine. There were also a number of forum members on ThirdGen.org that said it couldn’t be done. The flames were irreversibly stoked when Dirk was at a RadWood event. There was a ZR1 in attendance, so Dirk did some measuring and decided to go for it.

Just when it seems the world has gone bonkers over the LS-swap craze, seeing something so different and ingenious as Dirk’s LT5-powered Third-Gen Camaro is like a breath of fresh air. But you can bet transplanting that DOHC V8 and getting it running properly wasn’t exactly a walk in the park for Dirk. Although his installation does make it appear to be the case.

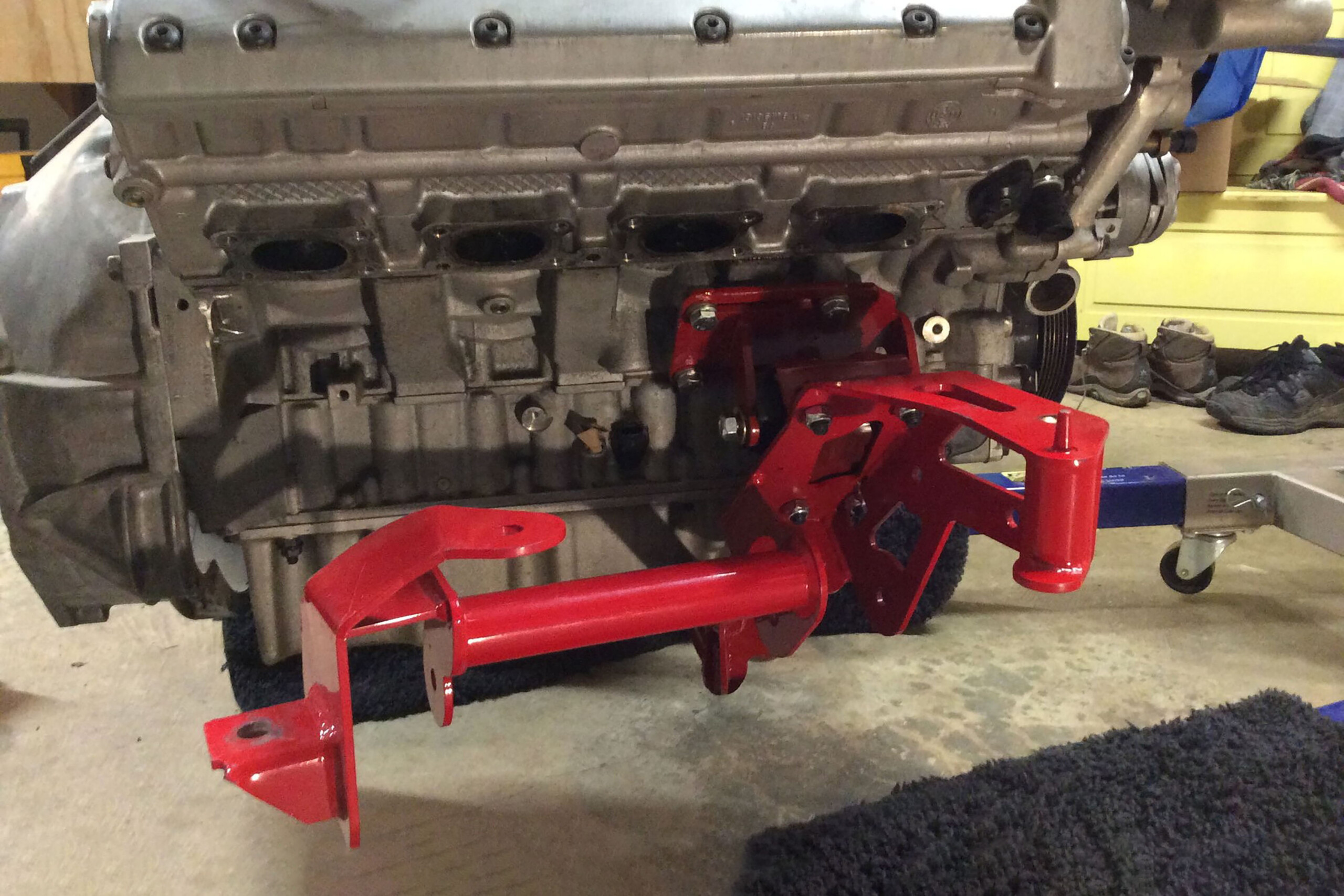

Stuffing a DOHC engine down into the underhood cavity required modifying several components for clearance, such as the headers and the K-member that now cradles the engine.

Transplanting an LT5 engine where an L98 once resided “takes some ingenuity and creativity”, says Dirk. He originally intended on running the LT5 very much like it was intended by the engineers so many years ago. In the end, it was decided to use some modern technology to help the engine run as well as possible.

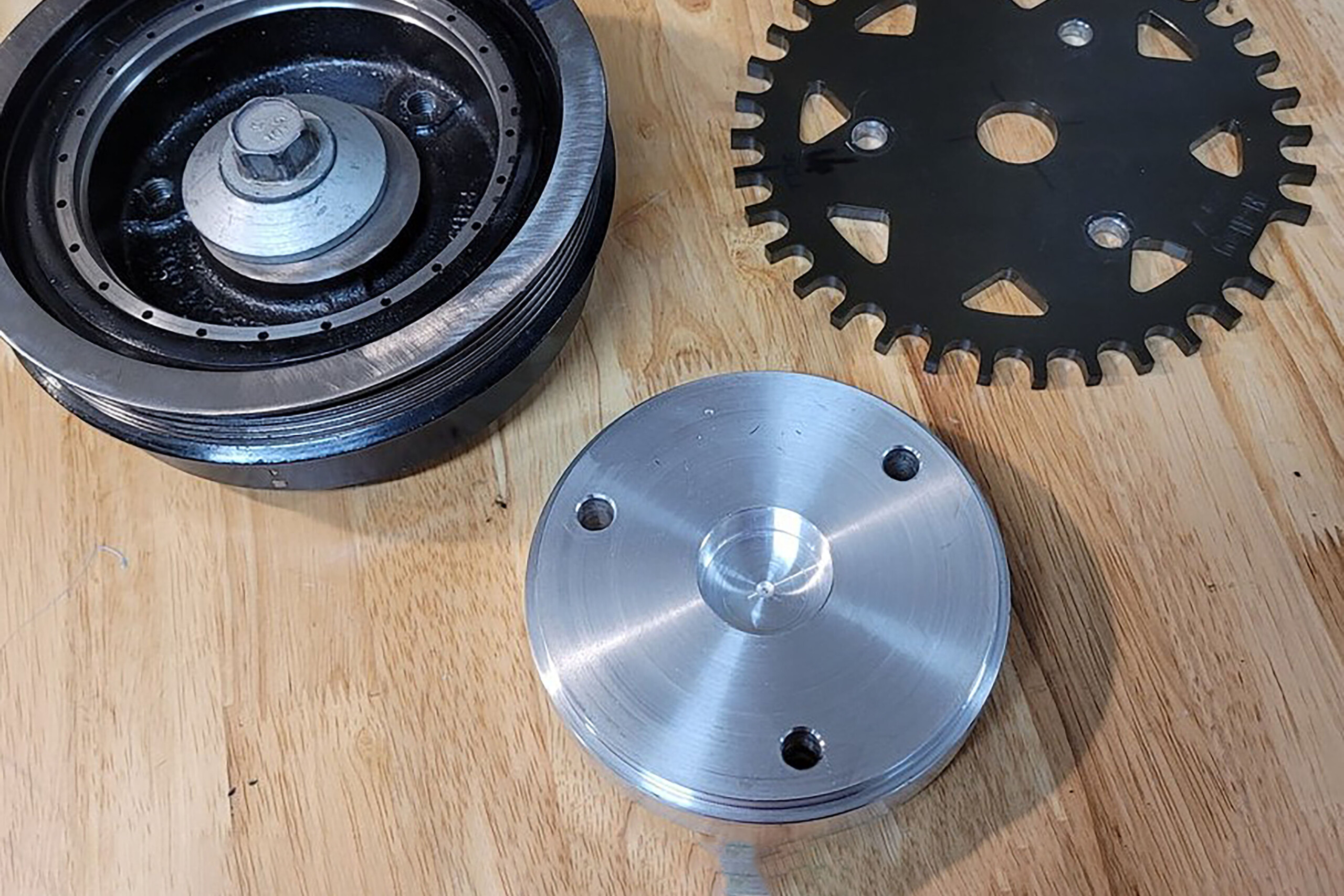

Dirk describes his engine control system best as, “treating it like an LS engine.” He replaced the LT5’s waste-fire coils with eight LS coils, using a custom mounting system under the intake plenum where the factory coils resided. He also eliminated the factory, vacuum-controlled secondary butterfly system in the now-ported intake. He built a custom wiring harness for the engine, which a MegaSquirt MS3 EVOPro ECM now controls. The system is timed with a custom crank trigger based on a Holley kit.

The ignition is timed through a modified “skipped-tooth” timing wheel and fires the LS-based coils with precision. Dirk is able to modify various components to make them work, such as the fuel block he machined for the fuel system’s pressure and return lines.

A modified UMI Performance K-member and Dirty Dingo motor mounts hold the engine in place and Dirk modified the 1997 LT1’s bell housing by removing the starter mounting points since the LT5’s starter is hidden in the cavity under the intake plenum. To help the LT5 breathe and yet provide room for the installation, Dirk modified a set of OBX Racing Sports ZR1 headers tucked into the Camaro’s engine bay and crossmember. From there, a Hooker Blackheart 2.5-inch, true-dual exhaust routes the fumes.

The LT5 engine gives a fair amount of room on each side, but having those centrally-located spark plugs is certainly a welcome engineering design, we’re sure!

Topside, the LT5 required some additional modifications to make everything operate as it should. Dirk machined a custom billet fuel block to route the fuel lines to the LT5’s existing fuel rails. He also fabricated a custom cold-air intake system to keep the fresh air flowing. Coolant lines were custom-fabbed and a modified Champion, three-row aluminum radiator, shroud, and fans help the high-revving engine keep its cool.

Driving The LT5-Powered IROC Camaro

As you can imagine, going from a Tune-Port Injected ride to the King of the Hill LT5 engine had a dramatic effect on how Dirk’s IROC performed. Of course, the additional upgrades he’s completed during the process only make the entire package much better. We asked Dirk what it was like to drive his Camaro. “Going LT5-powered from the 5.7-liter Tune-Port is like a totally different car”, he said. “Doubling the horsepower while adding a 7,000 RPM redline, that 2 1/2-inch Hooker Blackheart true-dual exhaust sounds like no other!”

Dirk had his engine dyno-tuned at CarbConn in Kirkland, Washington. In the end, the LT5 punched out 360 horsepower at 6,000 RPM and 351 lb/ft of torque at 4,400 RPM.

We’re pretty sure that Dirk now has his LT5-powered IROC Camaro just the way he likes it. Apparently, many others approve of the conversion as well. Last year, Dirk’s Camaro won the Best of Show at the Pacific Northwest Camaro Club’s All-Camaro event held in Dirk’s home state. He also took top honors on the ThirdGen.org site with the 2022 Car of the Year award!

The best part about this build is that Dirk and his son Cody did all the work to this level of detail. Sure, who wouldn’t love to have an LT5 in their ride? But this is more than just LT5-swapping a Third-Gen Camaro. The installation is as clean as any we’ve seen and the ingenuity to overcome obstacles is evident throughout. Dirk also gives credit to the many knowledgeable folks who have helped him along this journey, “A big shout out to my son Cody who was with me all the way, my very good friend Soloc4, Bruce and the crew at Hawks, Mario from the Dub Shop for the MegaSquirt tuning, Jerry’s gaskets, and Marc Haibeck, ZR1 expert extraordinaire.

Congratulations to Dirk (and Cody) for a job well done. We hope they both receive many smiles per gallon. And, if you happen to see a certain drop-top 1989 Chevy IROC Camaro running around the Pacific Northwest, tread softly, because you might find it is really the King of the Hill in sheep’s clothing!